Machine screws are essential fasteners used in various applications, offering durability and precision. A machine screw size guide helps in selecting the correct screw diameter, thread, and length for specific tasks, ensuring optimal performance and compatibility across materials.

Definition and Purpose

Machine screws are threaded fasteners designed to secure parts in machinery, electronics, and construction. They typically feature a cylindrical shaft with uniform threads and a shaped head for driving. Their purpose is to assemble components, distribute loads, and ensure structural integrity. Available in various materials like steel, stainless steel, or plastic, they are used with nuts or directly into tapped holes. The size and thread specifications are critical for ensuring proper fitment and performance in applications ranging from industrial equipment to consumer goods.

Common Applications

Machine screws are widely used in industrial machinery, automotive manufacturing, and construction projects. They are essential for assembling electronic devices, appliances, and furniture. These screws are also employed in aerospace for secure fastening and in DIY projects for versatility. Their durability and adaptability make them a go-to choice for various industries and applications requiring precision and strength. Proper sizing ensures reliability across different materials and environments, from softwood to metal and plastics.

Understanding Machine Screw Size Charts

Machine screw size charts are crucial for selecting the right screw, detailing diameter, threads per inch, and pilot hole sizes to ensure secure and precise fastening.

Importance of Size Charts

Machine screw size charts are vital for ensuring accurate fastening solutions. They provide precise measurements, including diameter, threads per inch, and pilot hole sizes, which are essential for proper installation. Using the correct screw size prevents damage to materials, enhances structural integrity, and ensures safety. Size charts also simplify the selection process, saving time and reducing errors. Proper sizing ensures compatibility with nuts, washers, and other components, guaranteeing optimal performance in industrial, automotive, and construction applications. Accurate sizing is critical for reliability and durability.

How to Read a Machine Screw Size Chart

Reading a machine screw size chart involves understanding key specifications like diameter, threads per inch (TPI), and length. Start by identifying the screw number or diameter, then refer to the chart for corresponding TPI and length options. Drill and tap sizes are also provided for proper installation. Match the screw size to pilot hole diameters for softwood or hardwood. Additionally, charts often include nut and washer sizes for compatibility. Use conversion charts for metric or US standards. Ensure accuracy to avoid installation errors and material damage, especially in materials like aluminum, brass, or plastics. Always consult torque specifications for safe tightening. Proper interpretation ensures optimal fastening solutions across applications, preventing loosening or breakage. This guide helps in selecting the right screw for any project, ensuring reliability and durability. By following the chart, users can avoid common mistakes and achieve secure, long-lasting connections in industrial, automotive, or construction settings. Always verify measurements before drilling or tapping to guarantee precise fits. This step-by-step approach simplifies the selection process, saving time and reducing errors. Ensure all components are compatible for optimal performance. Accurate reading of size charts is essential for successful projects.

Machine Screw Size Standards

Machine screw size standards ensure compatibility and consistency, with US (inch) and metric (millimeter) systems governing dimensions, threads, and materials, aiding precise screw selection for various applications.

US Machine Screw Standards

US machine screw standards are based on inch measurements, providing precise specifications for diameter, threads per inch (TPI), and length. These standards, often governed by ANSI, ensure compatibility across applications. Screw size designations typically include a number (e.g., #0 to #12) and thread count (e.g., 32 to 80 TPI). Common materials include steel, stainless steel, and brass, catering to industrial, automotive, and construction needs. Proper sizing ensures secure fastening and prevents damage. Always match screw size with appropriate drill and tap sizes for optimal results.

Metric Machine Screw Standards

Metric machine screw standards utilize millimeter measurements, with sizes ranging from M1.6 to M68. These standards ensure uniformity in diameter, pitch, and thread count. Common materials include stainless steel, steel, and brass, suitable for diverse applications. Thread specifications are precise, with coarse and fine options. Proper sizing is crucial for compatibility and performance. Always refer to metric thread charts for accurate drill and tap sizes. These standards are widely adopted globally, ensuring reliability and consistency in industrial and construction projects. Metric standards are user-friendly and provide comprehensive data for precise fastening solutions.

Conversion Between US and Metric Sizes

Converting US to metric machine screw sizes involves matching thread diameters and pitches. For example, a #6-32 UNF screw corresponds to M3.5×0.6 in metric. Charts provide decimal and millimeter equivalents, ensuring accurate transitions. This conversion is vital for international compatibility and avoids sizing discrepancies. Proper alignment of standards guarantees seamless integration in global manufacturing. Always use conversion tools or guides to match nominal sizes, threads per inch, and material specs accurately, ensuring optimal fitment and performance across different systems and applications.

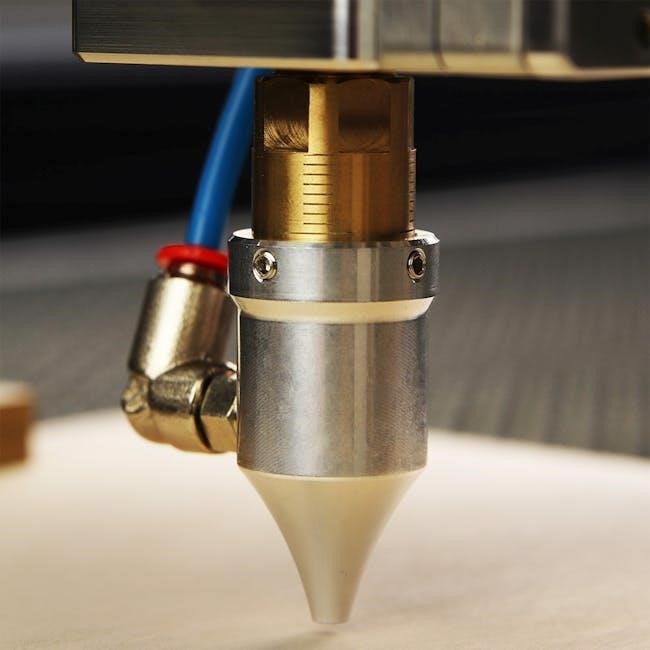

Types of Machine Screws

Machine screws come in various head types, including hex, flat, round, pan, and truss heads, each designed for specific applications and providing unique installation benefits and visual appeal.

Hex Head Machine Screws

Hex head machine screws are widely used for their durability and ease of installation. They feature a six-sided head that provides a secure grip, making them ideal for high-torque applications. Available in materials like stainless steel and carbon steel, they offer excellent resistance to corrosion and wear. Commonly used in construction, automotive, and industrial settings, hex head screws are favored for their strength and versatility. Their large head size allows for easy tightening with wrenches, ensuring a reliable connection in demanding environments.

Flat Head Machine Screws

Flat head machine screws are designed with a flat top and countersunk base, allowing them to sit flush with the material surface. This makes them ideal for applications requiring a smooth finish, such as furniture, appliances, and lightweight constructions. Available in materials like steel, stainless steel, and brass, they offer varying levels of strength and corrosion resistance. Their compact design and versatility make them suitable for both industrial and everyday use, ensuring secure fastening without protruding heads.

Round Head Machine Screws

Round head machine screws feature a rounded top and are commonly used in applications where a smooth, non-protruding surface is required. They are versatile and suitable for various materials, including metal and plastic. Available in materials like steel, stainless steel, and brass, they offer durability and corrosion resistance. Their design makes them ideal for machinery, electronics, and construction projects. Referencing a machine screw size guide ensures proper sizing for secure fastening and optimal performance in different environments and applications.

Pan Head Machine Screws

Pan head machine screws are characterized by their flat, rounded head with a short vertical side, making them ideal for applications requiring a low-profile fastening solution. They are widely used in electronics, automotive, and construction industries due to their versatility. Available in materials like steel, stainless steel, and brass, they offer durability and resistance to corrosion. Their design ensures secure fastening in tight spaces. When selecting pan head screws, a machine screw size guide helps determine the correct diameter and thread specifications for optimal performance.

Truss Head Machine Screws

Truss head machine screws feature a wide, flat head with a rounded top, offering a large bearing surface for added stability. They are commonly used in construction, furniture, and heavy-duty applications where a secure hold is critical. Available in materials like steel, stainless steel, and brass, they provide excellent durability and corrosion resistance. Their unique design makes them ideal for use in soft materials like wood. A machine screw size guide ensures proper selection, matching screw dimensions to specific project requirements for optimal performance and reliability.

Machine Screw Materials

Machine screws are crafted from diverse materials, including steel, stainless steel, brass, and plastic, each offering unique properties for strength, corrosion resistance, and suitability across various applications and environments.

Steel Machine Screws

Steel machine screws are widely used due to their high strength and durability. They are available in various types, including carbon steel and alloy steel, offering excellent resistance to wear and corrosion. Common applications include construction, automotive, and industrial machinery. Steel screws are often coated with zinc or phosphate for enhanced corrosion protection. They come in standard sizes, making them easy to integrate into existing systems. Their versatility and reliability make them a preferred choice for demanding environments where durability is critical. Proper torque and installation ensure optimal performance and longevity.

Stainless Steel Machine Screws

Stainless steel machine screws are highly corrosion-resistant, making them ideal for harsh environments. They are typically made from grades like 304 or 316, offering superior durability in marine or chemical-exposed applications. These screws are often used in medical equipment, food processing, and outdoor hardware due to their rust-resistant properties. Stainless steel screws are available in various sizes and thread types, ensuring compatibility with diverse materials. Their polished finish enhances aesthetics while maintaining strength. They are a popular choice for applications requiring both longevity and visual appeal.

Brass Machine Screws

Brass machine screws are known for their excellent corrosion resistance and conductivity, making them suitable for electrical and marine applications. They are durable yet non-magnetic, ideal for environments where steel might corrode. Brass screws are often used in lighting fixtures, plumbing, and decorative hardware. Their golden color adds an aesthetic appeal, while their softness makes them easy to machine. Available in various sizes, brass screws provide a balance between functionality and visual appeal, enhancing both performance and design in their applications.

Plastic Machine Screws

Plastic machine screws are lightweight and ideal for applications requiring corrosion resistance and electrical insulation. Made from materials like nylon or polycarbonate, they are perfect for environments where metal screws might rust or conduct electricity. These screws are commonly used in electronics, automotive components, and medical devices. Their flexibility and resistance to chemicals make them a versatile choice. Available in various sizes, plastic screws are cost-effective and durable, offering a practical solution for modern engineering challenges while minimizing weight and enhancing longevity in critical applications.

Thread Specifications

Thread specifications outline the screw’s diameter, threads per inch (TPI), and pitch, determining its grip strength and compatibility with materials like aluminum, brass, and plastics.

Thread Diameter

The thread diameter is a critical measurement in machine screws, determining compatibility with tapped holes. It is specified in decimal or fractional sizes, such as 0.060 inches for size number 0. Accurate measurement ensures proper fit and strength. Charts often list decimal and fractional equivalents, aiding selection for materials like aluminum or steel. Thread diameter directly impacts torque capacity and material compatibility, making it essential to reference size guides for precise applications. Using the correct diameter prevents assembly issues and ensures structural integrity in industrial and automotive applications.

Threads Per Inch (TPI)

Threads Per Inch (TPI) measures the number of threads along a screw’s length within one inch. Common TPI ranges from 64 to 80 for finer threads and 32 to 48 for coarser threads. Higher TPI values indicate finer threads, which are better for softer materials like plastic or aluminum, while lower TPI values provide coarser threads, ideal for harder materials. TPI is crucial for ensuring proper mating with tapped holes and achieving the desired holding power. Always consult a machine screw size guide to match TPI with specific applications for optimal performance and material compatibility.

Coarse vs. Fine Threads

Coarse threads have fewer threads per inch (TPI), typically ranging from 32 to 48, making them stronger and easier to engage. They are ideal for hard materials like metal and provide quicker assembly. Fine threads, with 64 to 80 TPI, offer better resistance against loosening and are suitable for softer materials like plastic or aluminum. A machine screw size guide helps determine the optimal thread type for specific applications, ensuring compatibility and performance. Choosing the right thread type is vital for durability and functionality in various industrial and construction projects. Always refer to standard charts for precise selections.

Drill and Tap Sizes

Drill and tap sizes are critical for proper screw fitment, ensuring accurate alignment and material compatibility. They guide pilot hole diameters for softwood, hardwood, and various materials, optimizing assembly precision.

Clearance Hole Drills

Clearance hole drills are used to create holes that allow machine screws to pass through without threading. The drill size is typically slightly larger than the screw’s major diameter to ensure smooth insertion. Proper clearance hole sizing prevents damage to the material and ensures proper alignment. The drill diameter is usually specified in size charts, corresponding to the screw size and type. Accurate sizing is crucial to avoid issues like screw misalignment or material splitting. Always refer to a machine screw size guide for precise clearance hole measurements to ensure optimal fit and performance.

Tap Drill Sizes

Tap drill sizes are critical for creating threaded holes that match machine screw dimensions. The drill size is determined by subtracting the screw’s thread depth from its major diameter. Using the correct tap drill ensures proper thread fit and prevents issues like stripped threads or over-tightening. Fine and coarse threads require different tap drill sizes, as specified in size charts. Incorrect sizing can lead to inconsistent threading or material damage. Always consult a machine screw size guide to select the appropriate tap drill for your application, ensuring precise and reliable results.

Pilot Hole Sizes

Pilot hole sizes ensure screws fit properly in materials without splitting. The size varies for softwood and hardwood, with specific charts guiding drill bit selection for accuracy and safety.

Softwood Pilot Holes

Softwood pilot holes are slightly smaller than the screw’s root diameter to prevent splitting. The hole diameter is typically 1/16 inch less than the screw’s major diameter. For example, a #6 screw requires a 3/32 inch pilot hole. Proper sizing ensures the wood does not crack and allows the screw to hold securely. Using a drill bit chart helps in selecting the correct size for different screw sizes and types, ensuring accurate installation and strength.

Hardwood Pilot Holes

Hardwood pilot holes are crucial for preventing splits in dense materials. They are typically drilled slightly smaller than the screw’s root diameter. For instance, a #6 screw needs a 5/64 inch pilot hole in hardwood. This precise sizing ensures the screw holds firmly without causing damage. Using a drill bit chart tailored for hardwood helps in selecting the correct size, promoting secure fastening and maintaining material integrity. Proper hole sizing is essential for optimal results in woodworking projects.

Machine Screw Torque Specifications

Torque specifications vary by screw material and size. Understanding these values ensures proper tightening, preventing damage. Always consult torque charts for precise guidance.

Understanding Torque Values

Torque values are critical for ensuring machine screws are tightened properly without causing damage. They vary based on screw material, size, and thread type. Stainless steel and brass screws, for instance, have different torque limits due to their material properties. Factors like friction and thread engagement also influence torque requirements. Always refer to torque charts for specific values, as over-tightening can strip threads, while under-tightening may lead to loose connections. Proper torque ensures reliability and safety in industrial, automotive, and construction applications.

Torque Charts for Different Materials

Torque charts provide specific values for machine screws based on material, ensuring proper tightening without damage. For steel screws, torque values are higher due to their strength, while stainless steel and brass require lower torque to prevent stripping. Plastic screws need minimal torque to avoid melting or deforming. These charts also account for thread engagement and friction, helping maintain joint integrity. Always consult material-specific charts to ensure safe and reliable fastening, as over-tightening can damage threads or surrounding material.

Washer and Nut Sizes

Washer sizes correspond to screw diameters, ensuring proper fitment and load distribution. Nut sizes match screw thread diameters, providing secure fastening. Proper sizing ensures durable, secure joints.

Washer Sizes

Washer sizes are determined by the screw’s diameter, ensuring proper fitment. They are typically made from materials like stainless steel or plastic. The size corresponds to the screw’s nominal diameter, with standard sizes ranging from small (e.g., 1/16 inch) to large (e.g., 1 inch or more). Proper sizing prevents over-tightening and ensures even load distribution. For example, a 1/2-inch washer pairs with a 1/2-inch screw. Accurate sizing is critical for secure fastening and longevity of the joint. Always match the washer size to the screw diameter for optimal performance.

Nut Sizes

Nut sizes are directly matched to the screw’s diameter and thread pitch. They are available in various materials, including steel, stainless steel, and brass. Standard sizes range from fine to coarse threads. Proper nut sizing ensures secure fastening without over-tightening. For example, a 1/2-inch nut fits a 1/2-inch screw. Correct sizing is crucial for load distribution and durability. Always refer to size charts to ensure compatibility, preventing stripped threads or loose connections. Accurate nut sizing enhances the overall integrity of the assembly.

Machine Screw Applications

Machine screws are widely used in industrial, automotive, and construction sectors. They are ideal for assembling components, ensuring structural integrity, and providing reliable fastening solutions across various materials and environments.

Industrial Applications

Machine screws are crucial in industrial settings for assembling machinery, equipment, and components. They are used in metal fabrication, electronics, and robotics. Their durability ensures reliability in high-stress environments. Stainless steel screws are favored in chemical plants for corrosion resistance. Proper sizing and torque are essential for safe and long-lasting performance. Machine screws facilitate smooth operations, ensuring efficiency in manufacturing and production processes. Their versatility makes them indispensable in various industrial applications, supporting structural integrity and precision across diverse systems.

Automotive Applications

Machine screws are fundamental in automotive manufacturing and repair. They secure engine components, suspension systems, and body panels. High-strength steel and stainless steel screws are commonly used to withstand vibrations and corrosion. Proper sizing ensures durability and safety in vehicles. For instance, metric screws are standard in European cars, while US sizes are used in domestic models. Torque specifications are critical to prevent damage and ensure reliability. Machine screws play a key role in maintaining vehicle performance and longevity, making them essential for automotive applications and maintenance.

Construction Applications

Machine screws are widely used in construction for assembling structural frames, decking, and fencing. They secure materials like wood, metal, and plastic, ensuring durability. Stainless steel and coated screws resist corrosion in outdoor conditions. Proper sizing is crucial for load-bearing applications, such as beams or roofing. Construction projects rely on machine screws for their strength and versatility, making them a fundamental component in building safe and durable structures; Correct installation ensures stability and longevity in various construction environments.

Best Practices for Using Machine Screws

Always use the correct screw size and torque to avoid material damage. Lubricate threads lightly and ensure proper alignment for secure fastening. Refer to size guides for compatibility.

Choosing the Right Screw

Selecting the right machine screw involves considering material type, thread specifications, and head style. Match screw diameter and thread count to the material’s density for proper grip. Use coarse threads for soft materials like wood and fine threads for metals. Refer to a machine screw size guide to ensure compatibility with pilot and clearance holes. Consider environmental factors like rust resistance for outdoor applications. Always choose screws with appropriate torque ratings to prevent over-tightening. Proper selection enhances durability and ensures secure fastening in any project.

Installation Tips

Pre-drill pilot holes to avoid splitting materials, using sizes from the machine screw size guide. Use a screwdriver with a tip that matches the screw head to prevent stripping. Ensure pilot holes are slightly smaller than the screw shank for softwoods and appropriately sized for hardwoods. Apply light lubrication for smoother insertion. Avoid overtightening, as it can damage threads or strip heads. Refer to torque charts for specific material guidelines. Proper alignment and even pressure ensure secure and lasting fastening.

Maintenance and Inspection

Regularly inspect machine screws for wear, corrosion, or loosening. Check for thread damage and head integrity using the machine screw size guide. Lubricate screws in high-friction environments to prevent seizing. Replace screws showing signs of wear or damage promptly. Use torque wrenches for consistent tightening and avoid over-tightening. Schedule periodic inspections, especially in harsh conditions, to ensure reliability and safety. Refer to torque charts for material-specific guidelines to maintain optimal performance and prevent failure.