Welcome to the 2023 Honda Civic Owners Manual! This guide helps you understand your vehicle’s features, maintenance, and safety systems for optimal performance and ownership experience․

Discover the advanced technology, fuel efficiency, and enhanced safety features designed to make your driving experience enjoyable and secure․ Refer to this manual for troubleshooting and customization tips․

Familiarize yourself with the dashboard, controls, and navigation system to maximize convenience․ Regular maintenance schedules and DIY tips are included to keep your Civic in top condition․

Explore the innovative upgrades and specifications that set the 2023 Honda Civic apart․ This manual is your key to unlocking the full potential of your new vehicle․

Importance of the Owners Manual

The 2023 Honda Civic Owners Manual is a vital resource for understanding your vehicle’s operation, maintenance, and safety features․ It provides essential information to ensure optimal performance, fuel efficiency, and longevity․ By following the manual, you can troubleshoot common issues, customize settings, and stay informed about advanced technologies․ Regularly reviewing the manual helps prevent potential damage and ensures compliance with legal standards․ It serves as a comprehensive guide for both new and experienced drivers, offering clear instructions for everyday use and maintenance․ This manual is your go-to reference for maximizing your driving experience and protecting your investment․

New Features in the 2023 Honda Civic

The 2023 Honda Civic introduces exciting upgrades, including an enhanced infotainment system with a larger touchscreen, wireless smartphone integration, and improved voice command functionality․ Safety is prioritized with advanced driver-assistance systems like adaptive cruise control and lane-keeping assist․ The new Civic also features a sport-tuned suspension for better handling and a more responsive driving experience․ Additionally, Honda has incorporated eco-friendly technologies to boost fuel efficiency, making it a more sustainable choice․ These innovations ensure the 2023 Honda Civic stands out as a modern, reliable, and feature-packed vehicle, offering both comfort and performance for drivers of all preferences․

Vehicle Information

Your 2023 Honda Civic is designed for exceptional performance and efficiency, featuring advanced engineering and innovative technology to enhance your driving experience and ensure long-term reliability․

2023 Honda Civic Specifications

The 2023 Honda Civic offers a range of powertrains, including a 2․0L naturally aspirated engine and a 1․5L turbocharged option, delivering up to 180 horsepower and 162 lb-ft of torque․ Available in sedan and hatchback styles, it features a 6-speed manual or CVT transmission․ With EPA ratings of up to 33 MPG city and 42 MPG highway, it combines efficiency with performance․ The Civic boasts a sport-tuned suspension for precise handling and a refined cabin with premium materials․ Advanced safety features, including Honda Sensing, and a 5-star safety rating ensure confidence on the road․ Its modern design and cutting-edge technology make it a standout in its class․

Key Features of the 2023 Honda Civic

The 2023 Honda Civic stands out with its sleek design, featuring LED headlights and a aggressive front grille․ Inside, it offers a spacious cabin with premium materials, heated front seats, and a power-adjustable driver’s seat․ The infotainment system includes a high-resolution 9-inch touchscreen, Apple CarPlay and Android Auto integration, and a premium Bose audio system․ Safety is enhanced with Honda Sensing, including adaptive cruise control, lane-keeping assist, and traffic jam assist․ With Sport and Touring trims available, the Civic delivers a blend of style, comfort, and advanced technology, making it a top choice for modern drivers․

Technical Details and Upgrades

The 2023 Honda Civic offers a 2․0L naturally aspirated engine producing 158 horsepower and 138 lb-ft of torque, or a 1․5L turbocharged engine delivering 180 horsepower and 162 lb-ft of torque․ Both engines are paired with a CVT or 6-speed manual transmission for smooth performance․ The suspension system has been refined for improved handling and ride comfort․ Technology upgrades include a new 9-inch HD touchscreen, wireless Apple CarPlay and Android Auto, and expanded USB-C ports․ The Civic also features enhanced noise insulation and structural rigidity for a quieter, more refined driving experience, solidifying its reputation as a reliable and modern compact car․

Instrument Panels and Controls

The 2023 Honda Civic features an intuitive dashboard with a digital instrument cluster and analog gauges․ Controls are logically arranged for easy access to climate, audio, and driving functions․

Understanding the Dashboard Layout

The 2023 Honda Civic’s dashboard is designed for clarity and convenience․ The central digital instrument cluster displays vital information like speed, fuel level, and navigation․ Analog gauges for RPM and temperature are positioned for easy viewing․ Controls for climate, audio, and driver-assistance systems are logically grouped․ The touchscreen infotainment system dominates the center, offering intuitive access to settings and features․ Illuminated buttons and soft-touch materials enhance the premium feel․ This layout ensures drivers can focus on the road while maintaining easy access to essential functions, creating a seamless and enjoyable driving experience․

Location and Function of Controls

The controls in the 2023 Honda Civic are strategically placed for ease of access․ Steering wheel-mounted buttons manage audio, cruise control, and driver-assistance systems․ The gearshift and parking brake are centrally located for intuitive operation․ Climate controls, including temperature and fan settings, are positioned below the infotainment screen․ The touchscreen interface provides access to navigation, Bluetooth connectivity, and vehicle settings․ Rearview camera controls and hazard light buttons are within easy reach on the dashboard․ This ergonomic design ensures drivers can operate essential functions without distraction, enhancing both safety and convenience during the drive․

Customizing Your Vehicle Settings

The 2023 Honda Civic allows you to tailor your driving experience through customizable settings․ Use the touchscreen to adjust display preferences, audio settings, and driver-assistance features like adaptive cruise control․ Personalize your infotainment system by setting favorite radio stations and pairing Bluetooth devices․ Climate control settings can also be fine-tuned for comfort․ Additionally, the Civic offers customizable driver profiles, enabling multiple users to save their preferred settings for seat position, mirror adjustments, and infotainment preferences․ Voice command functionality further enhances convenience, allowing hands-free control of various features․ Explore these options to create a driving environment that suits your lifestyle and preferences․

Maintenance and Servicing

Regular maintenance ensures your 2023 Honda Civic runs efficiently․ Follow the recommended schedule for oil changes, tire rotations, and inspections to maintain performance and warranty compliance․

Scheduled Maintenance Requirements

Regular maintenance is crucial for the longevity and performance of your 2023 Honda Civic․ Adhere to the recommended schedule outlined in this manual, including oil changes every 5,000 to 7,500 miles, tire rotations, and brake inspections․

Follow the maintenance milestones at 15,000, 30,000, and 60,000 miles for optimal performance․ Neglecting scheduled maintenance may lead to reduced fuel efficiency, increased emissions, and potential damage to engine components․ Always use genuine Honda parts and consult a certified technician for servicing to ensure warranty compliance and maintain your vehicle’s reliability and safety on the road․

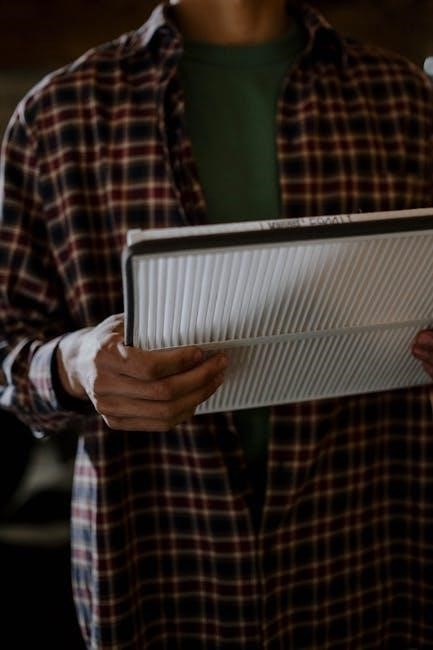

DIY Maintenance Tips

Performing routine DIY maintenance can help keep your 2023 Honda Civic in excellent condition․ Start with regular oil changes using the recommended viscosity for your climate․ Check and maintain proper tire pressure, as specified in the manual, to improve fuel efficiency and handling․

Inspect and replace the air filter every 15,000 to 30,000 miles to ensure optimal engine performance․ Additionally, monitor the battery terminals for corrosion and clean them if necessary․ For brake pads, inspect for wear and replace them when thickness falls below 1/8 inch․ Always refer to your owner’s manual for specific guidelines and safety precautions before starting any DIY maintenance․

Resetting the Maintenance Light

To reset the maintenance light on your 2023 Honda Civic, start by turning the ignition to the “ON” position without starting the engine․ Use the steering wheel controls to navigate to the “Settings” or “Vehicle Health” menu․ Select “Maintenance” and choose the option to reset the maintenance light or due service reminder․ Confirm the reset, and the light should turn off․ If the light remains on, repeat the process or consult a professional․ This simple procedure allows you to keep track of your vehicle’s maintenance needs accurately․

Safety Features

The 2023 Honda Civic is equipped with advanced safety technologies, including collision mitigation, lane-keeping assist, and adaptive cruise control․ These features enhance driver confidence and vehicle protection․

Advanced Safety Technologies

The 2023 Honda Civic features cutting-edge safety innovations․ The Honda Sensing® suite includes Collision Mitigation Braking, Lane Keeping Assist, and Adaptive Cruise Control․ These technologies work seamlessly to prevent accidents and enhance driver confidence․ The system uses cameras and sensors to monitor the road, providing alerts and interventions when necessary․ Additionally, the Civic offers a multi-angle rearview camera and automatic high beams, ensuring superior visibility and safety in various driving conditions․ These advanced features make the 2023 Honda Civic one of the safest vehicles in its class, prioritizing the well-being of both drivers and passengers․

Understanding Airbag Systems

The 2023 Honda Civic is equipped with a comprehensive airbag system designed to provide superior protection in the event of a collision․ The vehicle features multiple airbags, including front, side, and curtain airbags, which deploy strategically to minimize injury․ The system is integrated with sensors that detect the severity and type of impact, ensuring optimal deployment force․ Additionally, the airbags work in conjunction with seatbelts to maximize occupant safety․ It is essential to follow the manufacturer’s guidelines for proper use and maintenance of this system, as outlined in the owners manual, to ensure its reliability and effectiveness in emergency situations․

Seatbelt and Child Safety Features

The 2023 Honda Civic prioritizes occupant safety with advanced seatbelt and child safety features․ All seats are equipped with three-point seatbelts, and the rear seats feature the LATCH (Lower Anchors and Tethers for Children) system for secure child seat installation․ The vehicle includes a seatbelt reminder system to ensure all occupants are properly restrained․ Additionally, the Civic offers child-safe rear door locks to prevent accidental opening․ These features, combined with the robust airbag system, provide a safe environment for passengers of all ages․ The owners manual provides detailed guidance on proper seatbelt use and child seat installation for optimal protection․

Driving Tips

Optimize fuel efficiency with Eco Mode, ensure smooth acceleration, and maintain safe distances․ Regular tire checks and proper vehicle loading enhance performance and safety for a better driving experience․

The 2023 Honda Civic offers an Eco Mode to enhance fuel efficiency by optimizing engine performance and reducing energy consumption․ Activate Eco Mode for improved mileage in city driving conditions․ Combine Eco Mode with steady speeds and gentle acceleration for maximum efficiency․ Regular tire pressure checks and proper vehicle maintenance further support fuel economy and overall performance․ The 2023 Honda Civic delivers exceptional performance through its refined engine and advanced transmission systems․ For optimal driving, use the Eco Mode for fuel efficiency or switch to Sport Mode for a more dynamic experience․ Regularly check and maintain proper tire pressure, as this enhances handling and fuel economy․ Ensure your vehicle is serviced according to the recommended schedule in the owner’s manual to keep it running at peak performance․ Additionally, avoid extreme temperatures and ensure proper fluid levels to maintain engine health․ By following these tips, you can enjoy a smooth and powerful driving experience in your Honda Civic․ Always wear your seatbelt and ensure all passengers do the same․ Properly secure child seats and restraints to ensure safety for younger passengers․ Adhere to speed limits and maintain a safe distance from other vehicles․ Avoid distractions like using your phone while driving․ Be aware of your surroundings, especially in low visibility conditions․ Use headlights appropriately and ensure mirrors are adjusted for optimal visibility․ Familiarize yourself with the Honda Sensing® suite of safety features, such as collision mitigation and lane-keeping assist, to enhance your driving safety․ Regularly check tire pressure and brakes to maintain vehicle safety and performance․ The 2023 Honda Civic features an advanced infotainment system with a high-resolution touchscreen, seamless Bluetooth connectivity, and integrated navigation for a convenient and enjoyable driving experience․ The 2023 Honda Civic’s touchscreen system is user-friendly and responsive․ Access features like navigation, audio, and climate control with intuitive taps and swipes․ Customize home screens to prioritize frequently used functions․ Voice command integration allows hands-free operation, enhancing safety and convenience․ The system supports Apple CarPlay and Android Auto for seamless smartphone integration․ Adjust settings like brightness and wallpaper to personalize your experience․ Regular software updates ensure optimal performance and new feature additions․ Explore the menu options to discover all capabilities and tailor the interface to your preferences for a more enjoyable and connected drive․ To connect your smartphone to the 2023 Honda Civic, enable Bluetooth on your device and ensure it is in pairing mode․ Select “Bluetooth” in the vehicle’s touchscreen menu, and confirm the connection․ Once paired, you can access calls, messages, and music seamlessly․ Voice commands allow hands-free control for enhanced safety․ For troubleshooting, restart your phone or vehicle, and ensure Bluetooth is enabled․ Regular software updates maintain compatibility and optimize performance․ This feature ensures a connected and convenient driving experience, integrating your smartphone’s functionality with the Civic’s advanced infotainment system․ The 2023 Honda Civic features an advanced navigation system designed for seamless route planning․ Enter destinations using voice commands or the touchscreen interface for convenient operation․ The system provides turn-by-turn directions, real-time traffic updates, and alternate route suggestions to avoid congestion․ Points of interest, such as gas stations or restaurants, are easily accessible․ Regular map updates ensure accurate and up-to-date information․ The navigation system integrates with the infotainment display, offering a user-friendly experience․ Whether commuting or exploring new areas, Honda Navigation enhances your driving experience by providing clear guidance and minimizing travel time, ensuring you reach your destination efficiently and stress-free․ The 2023 Honda Civic Owners Manual provides guidance for resolving common issues, interpreting error codes, and resetting systems․ Refer to this section for solutions to maintain peak performance and address concerns promptly․ The 2023 Honda Civic Owners Manual addresses common issues such as warning light notifications, connectivity problems, and navigation glitches․ For warning lights, check the manual to identify their meaning and resolve the issue promptly․ Connectivity issues with Bluetooth or smartphone pairing can often be fixed by restarting the infotainment system or resetting device connections․ Navigation glitches may require updating the map software or recalibrating the system․ Always refer to the troubleshooting section for step-by-step solutions to ensure your vehicle operates smoothly․ Regular updates and maintenance can prevent many of these issues, enhancing your overall driving experience․ The 2023 Honda Civic Owners Manual provides detailed explanations for warning lights on your dashboard․ These indicators signal important information about your vehicle’s status․ The manual categorizes lights by color: red for critical issues like engine or brake problems, yellow for system notifications such as maintenance needs, and green or blue for operational statuses like high beams or cruise control․ Familiarize yourself with each symbol to address issues promptly․ Ignoring warning lights can lead to more severe problems․ Refer to the manual for accurate interpretations and recommended actions to ensure your safety and maintain your vehicle’s optimal performance․ Resetting the diagnostic system in your 2023 Honda Civic is essential after addressing issues or clearing trouble codes․ Locate the “Trip” button on the dashboard and press it until the odometer displays zeros․ Turn the ignition to the “ON” position without starting the engine․ Press and hold the “Reset” button until the dashboard lights flash․ Release and press again to confirm․ This process clears stored fault codes and resets the system․ If issues persist, consult a professional technician․ Always refer to the manual for specific instructions to ensure proper reset procedures and maintain your vehicle’s diagnostic accuracy․ Your 2023 Honda Civic complies with all applicable safety and emissions standards․ Ensure compliance with local laws and regulations․ Refer to the manual for warranty details and emissions information․ Your 2023 Honda Civic is backed by a comprehensive warranty program designed to protect your investment․ The basic warranty covers parts and labor for defects in materials or workmanship for a specified period or mileage․ Additionally, the powertrain warranty provides extended coverage for critical engine and transmission components․ Regular maintenance, as outlined in the manual, is essential to ensure warranty validity․ For detailed terms and conditions, refer to the warranty section in your manual or contact Honda support․ This program reflects Honda’s commitment to quality and customer satisfaction, ensuring peace of mind throughout your ownership experience․ The 2023 Honda Civic is designed and manufactured to meet or exceed all applicable safety, emissions, and regulatory standards in regions where it is sold․ This includes compliance with federal and local regulations for environmental protection, noise reduction, and occupant safety․ Honda ensures adherence to global standards, such as those set by the U․S․ Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA)․ The vehicle is also equipped with advanced safety technologies to meet stringent crash test ratings․ By complying with these standards, the Civic contributes to a safer and more sustainable driving environment for all road users․ The appendices provide a glossary of technical terms, contact information for Honda support, and supplementary materials for further reference, ensuring comprehensive understanding of your vehicle’s features and maintenance․ The glossary section defines key automotive and technical terms related to the 2023 Honda Civic, ensuring clarity for owners․ It explains components like ABS, ECO mode, and infotainment systems, helping users understand their vehicle’s technology and features․ This resource aids in troubleshooting and maintenance by providing clear definitions of industry-specific jargon․ Whether you’re a new driver or a seasoned owner, the glossary serves as a quick reference guide to enhance your understanding and operation of the Honda Civic․ It covers all aspects of the vehicle, from performance to safety features, making it an essential tool for every owner․ For any inquiries or assistance regarding your 2023 Honda Civic, contact Honda’s customer support team․ Visit the official Honda website for regional contact details․ You can reach Honda’s customer service at 1-800-999-1009 (available 24/7) or email support@honda․com․ Additionally, your local Honda dealership can provide personalized assistance․ For technical support or navigation-related questions, refer to the Honda Navigation Center at 1-877-999-7870․ International customers should check the Honda global website for country-specific contact information․ This section ensures you have all necessary resources to address any concerns promptly and effectively․Eco Mode and Fuel Efficiency

Optimizing Performance

Safe Driving Practices

Infotainment and Navigation

Using the Touchscreen System

Connecting Bluetooth and Smartphones

Navigating with Honda Navigation

Troubleshooting

Common Issues and Solutions

Understanding Warning Lights

Resetting the Diagnostic System

Legal and Regulatory Information

Warranty Information

Compliance and Regulatory Standards

Appendices

Glossary of Terms

Contact Information for Support