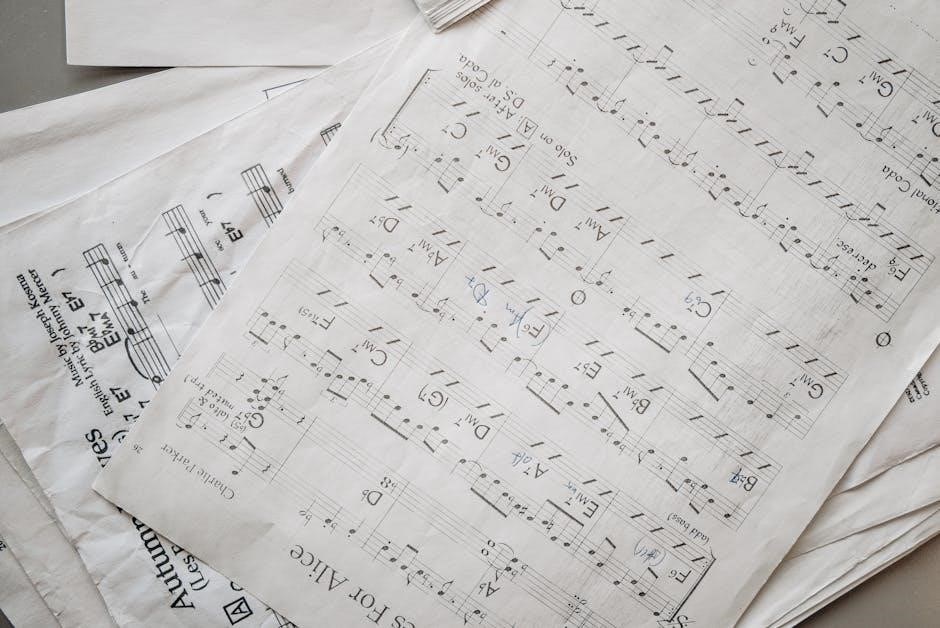

Guitar chord progressions are the harmonic foundation of countless songs. Understanding them unlocks songwriting and improvisation skills, offering a pathway to musical expression.

What are Chord Progressions?

Chord progressions are simply a sequence of chords played one after another. They form the harmonic structure of a song, providing the underlying foundation for melody and rhythm. Think of them as the roadmap for a musical journey, guiding the listener through a series of emotional and sonic landscapes.

Instead of randomly stringing chords together, musicians intentionally choose progressions that create a specific feeling or effect. These choices are often based on established musical principles and conventions, but also allow for creative experimentation.

Each chord within a progression has a function – tonic (home base), dominant (creates tension), subdominant (leads towards the tonic), and so on. Recognizing these functions helps you understand why certain progressions sound pleasing or create particular moods. A progression isn’t just a list of chords; it’s a relationship between them, a story told through harmony.

Understanding chord progressions is crucial for both playing and writing music. It allows you to anticipate changes, improvise effectively, and craft your own compelling songs.

Why are Chord Progressions Important?

Chord progressions are the backbone of musical composition, providing structure and emotional context. They’re far more than just a series of chords; they dictate the feeling of a song, influencing whether it sounds happy, sad, tense, or relaxed.

For guitarists, understanding progressions unlocks improvisation skills. Knowing which chords naturally follow each other allows you to create solos and fills that complement the song’s harmony, rather than clashing with it. It also simplifies learning new songs – recognizing the progression means you’re already halfway there!

Songwriters rely heavily on chord progressions to build their ideas. A well-chosen progression can inspire melodies and lyrical themes, providing a solid foundation for a complete song. Familiar progressions offer a starting point, while variations can add originality.

Ultimately, mastering chord progressions empowers you to communicate musically, both as a performer and a creator. They are the essential building blocks for musical fluency.

Basic Chord Progressions for Beginners

Let’s explore fundamental progressions! These simple sequences are perfect for new guitarists, building a strong harmonic foundation and unlocking countless song possibilities.

I-IV-V Progression: The Foundation

The I-IV-V progression is arguably the most important chord progression to learn on guitar. It’s the bedrock of countless songs across genres – rock, blues, country, pop, and more. In any key, these three chords create a satisfying and complete harmonic movement.

Let’s break it down: the ‘I’ chord is the tonic, the home base of the key. The ‘IV’ chord provides a gentle lift, creating tension, and the ‘V’ chord builds even more tension, strongly resolving back to the ‘I’ chord. This cycle is incredibly pleasing to the ear.

For example, in the key of G, the I-IV-V progression is G-C-D. In the key of C, it’s C-F-G. Experiment with different strumming patterns and rhythms over this progression. You’ll quickly realize how versatile it is. Mastering this progression will open doors to understanding and playing a vast repertoire of music. It’s a fantastic starting point for improvisation and songwriting, allowing you to build melodies and solos on a solid harmonic base.

ii-V-I Progression: A Jazzy Start

The ii-V-I progression is a cornerstone of jazz harmony, but its usefulness extends far beyond that genre. It creates a smoother, more sophisticated sound than the I-IV-V, offering a richer harmonic palette for guitarists. This progression relies on a slightly more complex movement, building tension and release in a unique way.

The ‘ii’ chord acts as a pre-dominant, leading naturally to the ‘V’ chord, which is the dominant. The ‘V’ chord then strongly resolves to the ‘I’ chord, the tonic. This creates a compelling harmonic pull. Think of it as a slightly more refined version of the I-IV-V.

In the key of C, the ii-V-I progression is Dm-G-C. In the key of G, it’s Am-D-G. Experiment with adding seventh chords (Dm7, G7, Cmaj7) to further enhance the jazzy feel. This progression is frequently used in intros, turnarounds, and as a harmonic foundation for improvisation; It’s a crucial building block for understanding more advanced harmonic concepts and expanding your musical vocabulary on the guitar.

I-vi-IV-V Progression: The Pop Standard

The I-vi-IV-V progression is arguably the most ubiquitous chord progression in modern pop music. Its popularity stems from its pleasing, emotionally resonant quality and its versatility across various genres. You’ve almost certainly heard it countless times, even if you don’t recognize it by name! It’s a cornerstone of songwriting for a reason.

This progression creates a sense of movement and longing, often associated with themes of love, loss, or reflection. The move to the vi chord (the relative minor) introduces a touch of melancholy before resolving back to the tonic (I). The IV and V chords then provide a familiar and satisfying harmonic resolution.

In the key of C, this translates to C-Am-F-G. In G, it’s G-Em-C-D. Experiment with different strumming patterns and voicings to create unique textures. This progression is incredibly adaptable and forms the basis for countless hit songs. Mastering it is essential for any aspiring songwriter or guitarist wanting to understand the language of popular music.

Common Chord Progressions in Popular Music

Popular songs frequently utilize established chord progressions. Recognizing these patterns unlocks understanding of song structure and provides a foundation for analysis.

The 12-Bar Blues Progression

The 12-bar blues is a cornerstone of modern music, deeply rooted in African American musical traditions. This progression, typically in a 4/4 time signature, forms the basis for countless blues, rock, and jazz songs. It’s characterized by a specific sequence of chords, usually I, IV, and V, repeated over twelve measures.

A standard 12-bar blues progression in the key of E would look like this:

- E7 (4 bars)

- E7 (2 bars)

- A7 (2 bars)

- E7 (2 bars)

- B7 (1 bar)

- A7 (1 bar)

- E7 (2 bars)

The seventh chords (E7, A7, B7) add a characteristic bluesy flavor. Variations exist, but this structure remains fundamental. Mastering this progression is crucial for any guitarist wanting to explore blues improvisation and understand its influence on other genres. It’s a fantastic starting point for learning about harmonic structure and developing a feel for rhythmic phrasing.

I-V-vi-IV Progression: The “Sensitive Female” Progression

Often playfully dubbed the “Sensitive Female” progression (though its use extends far beyond songs about those themes!), this chord sequence – I-V-vi-IV – is remarkably prevalent in pop music. Its emotional resonance stems from the movement between major and minor chords, creating a sense of longing and resolution. It’s incredibly versatile and adaptable to various tempos and styles.

In the key of C, this translates to:

- Cmaj (I)

- Gmaj (V)

- Am (vi)

- Fmaj (IV)

This progression’s popularity exploded in the late 20th and early 21st centuries, appearing in countless hits. Its appeal lies in its simplicity and emotional depth. It’s a fantastic progression for songwriters seeking to evoke feelings of nostalgia, vulnerability, or introspection. Experimenting with different voicings and strumming patterns can dramatically alter its character, making it a truly adaptable tool for any guitarist.

vi-IV-I-V Progression: A Variation on a Theme

This progression, vi-IV-I-V, offers a subtle yet significant shift in emotional color compared to its more common cousin, the I-V-vi-IV. Starting on the minor vi chord immediately establishes a mood of introspection or melancholy, before resolving towards the brighter I and V chords. It’s a fantastic choice for creating a sense of yearning or bittersweetness.

Let’s look at it in the key of A:

- Am (vi)

- Dmaj (IV)

- Amaj (I)

- Emaj (V)

While sharing harmonic elements with the “Sensitive Female” progression, this variation feels less predictable and more nuanced. It’s frequently used in introspective ballads and songs aiming for a more sophisticated emotional palette. Don’t hesitate to experiment with adding seventh chords or passing chords to further enrich the harmonic texture and create unique sonic landscapes. It’s a powerful tool for crafting emotionally resonant music.

Expanding Your Chord Progression Knowledge

Beyond the basics, explore harmonic depth! Seventh chords, passing chords, and inversions unlock richer sounds and more complex, interesting musical arrangements.

Using Seventh Chords

Seventh chords add a layer of sophistication and color to your chord progressions, moving beyond the simplicity of major and minor triads. They achieve this by including the seventh degree of the scale, creating a more complex harmonic texture. Common types include major seventh (maj7), minor seventh (m7), dominant seventh (7), and half-diminished seventh (m7b5).

Incorporating seventh chords isn’t about replacing triads entirely; it’s about strategically using them to create tension and release. A dominant 7th chord, for example, strongly resolves to the tonic, adding a compelling pull. Experiment with substituting a major or minor triad with its seventh chord counterpart. For instance, replace a C major chord with a Cmaj7 for a smoother, jazzier feel.

Don’t be afraid to mix and match! A progression like Cmaj7 ⎻ Am7 ⎼ Dm7 ⎻ G7 demonstrates how seventh chords can create a lush and dynamic harmonic landscape. Learning to voice these chords effectively on the guitar – finding comfortable and musical fingerings – is key to unlocking their full potential. Many guitar chord progressions pdf resources detail these voicings.

Adding Passing Chords

Passing chords are non-diatonic chords used to create smoother transitions between primary chords in a progression. They add harmonic interest and a sense of movement, preventing progressions from sounding static or predictable. These chords typically appear briefly, acting as a bridge between two more stable harmonies.

Common types include diminished chords and secondary dominants. A diminished chord often connects chords a whole step apart, while a secondary dominant creates a stronger pull towards its target chord. For example, in a C-G-Am-F progression, you could insert a Ddim between C and G.

Experimenting with chromatic passing chords – chords that lie outside the key – can also yield interesting results. The key is subtlety; passing chords should enhance, not distract from, the main harmonic flow. Many guitar chord progressions pdf guides illustrate effective passing chord voicings. Remember to listen carefully to how each passing chord affects the overall sound and adjust accordingly. They’re a fantastic way to personalize your songwriting!

Chord Inversions and Voicings

Chord inversions change which note of the chord is in the bass, altering its sonic character and creating smoother bass lines between chord changes. Instead of a standard C major (C-E-G), you can play C/E (E-G-C) or C/G (G-C-E). This subtle shift can dramatically impact the progression’s feel.

Voicings refer to the specific arrangement of notes within a chord. Different voicings can create varied textures – open, close, spread out, or compact. Experimenting with voicings on the guitar allows you to find unique sounds and avoid muddy or repetitive harmonies.

Many guitar chord progressions pdf resources demonstrate various inversions and voicings for common chords. Mastering these techniques allows for greater control over the harmonic landscape of your music. Consider the overall texture you want to achieve; a higher voicing can sound brighter, while a lower voicing can feel grounded. Don’t be afraid to explore and find what resonates with your ear!

Resources for Learning More

Numerous guitar chord progressions pdf documents are available online, offering comprehensive charts and analyses; Websites and books provide further theoretical understanding.

Online Chord Progression Generators

Several websites offer fantastic online chord progression generators, proving incredibly useful for sparking creativity and overcoming writer’s block. These tools allow you to input parameters like key, desired mood (happy, sad, energetic, etc.), and complexity, then generate a variety of chord sequences. Many also visualize the progressions, showing you how they relate to the chosen key and scale.

While not directly guitar chord progressions pdf resources, these generators can inform your study of PDFs. You can use a generated progression, then find a PDF chart to analyze the chords in detail – their inversions, voicings, and potential substitutions. Some generators even allow exporting progressions in formats compatible with music notation software, facilitating further analysis.

Popular options include Hooktheory, Scaler 2 (which has a web-based component), and various free tools found with a quick web search. Experimenting with these generators can broaden your harmonic vocabulary and provide inspiration for your own songwriting, complementing your learning from PDF resources.

Recommended Chord Progression PDF Resources

Numerous excellent guitar chord progression PDF resources are available online, catering to various skill levels. A great starting point is searching for “common chord progressions guitar pdf” – this yields charts detailing progressions in popular keys like G, C, D, and E. These often include diagrams showing finger positions for each chord, making them ideal for beginners.

Websites like Ultimate-Guitar.com and various music education blogs frequently host downloadable PDFs. Look for resources that categorize progressions by genre (blues, jazz, pop, rock) to focus your learning. More advanced PDFs might delve into harmonic analysis, explaining why certain progressions work so well.

Consider searching for PDFs specifically focused on songwriting. These often present progressions alongside lyrical prompts or melodic ideas. Remember to critically evaluate the source; look for well-organized, clearly presented charts from reputable music educators. Utilizing these guitar chord progressions pdf materials will significantly enhance your understanding.

Further Study: Music Theory Basics

Delving into music theory dramatically deepens your comprehension of guitar chord progressions. Understanding concepts like intervals, scales, and key signatures unlocks the logic behind why certain chords sound good together. Knowing the Roman numeral system (I, IV, V, etc.) allows you to transpose progressions to any key effortlessly.

Resources beyond simple guitar chord progressions pdf charts become invaluable. Explore online courses or textbooks covering harmony and counterpoint. Learning about chord qualities (major, minor, diminished, augmented) explains the emotional color each chord brings to a progression.

Focus on understanding the circle of fifths – a visual representation of key relationships. This helps predict common chord changes and build more sophisticated progressions. While PDFs provide the ‘what,’ music theory provides the ‘why,’ empowering you to create your own unique and compelling harmonic structures. This foundational knowledge is crucial for musical growth.